|

Carbon nanotubes (CNTs) have ultrahigh strength, high electrical conductivities, high thermal conductivities, electric field emissions, gas sensitivities, and other functional properties. These outstanding mechanical, physical, and multifunctional properties of CNTs, in combination with their unique 1D nanostructures with high specific areas, allow for a wide range of potential applications such as structural fibers, composites, multifunctional fabrics, and devices. The fabrication of CNTs into a continuous multifunctional CNT yarn is an important step towards these macroscopic applications. Several processes are under development to fabricate macroscopic CNT fibers, including wet spinning of CNTs from polymer dispersions or acid dispersions, dry spinning from aligned CNT matrices, and direct spinning from chemical vapor deposition (CVD) reactions. While the development of a continuous and weavable pure CNT yarn remains a major challenge in the fabrications, CNT yarns so far obtained from the different processes are monolithic in structure, although a hollow yarn was demonstrated from a wet drawing process. One the other hand, CNTsheets or films have been fabricated by drying CNT dispersions, drawing or infiltrating of CNT arrays, and by CVD spinning. These 2D CNT assemblies have demonstrated applications as catalyst supports, molecular sieves, infiltrators, conductors, electromagnetic shields, capacitors, and artificial tissues. If CNTs can be made into continuous yarns with a layered structure, they will combine the weavable property of fibers and the structural characteristic of films and can be adopted for numerous applications.

In the present work, we report the fabrication of a novel continuous yarn of CNTs with a multiple-layer structure by the CVD spinning process. The yarn consists of multiple monolayers of CNTs concentrically assembled in seamless tubules along the yarn axis. The development of a water-densification and spinning process allows us to spin the CNT yarn continuously with a yarn length of over several kilometers and a yarn quality close to conventional textile yarns. The CNTyarn can be controlled to be either hollow or monolithic with compacted or detached CNT monolayers by controlling the spinning process. This layered multifunctional CNT yarns combine superior mechanical properties, electrical conductivities, and surface structures, and have potential applications as structural fibers, composites, woven fabrics, catalyst supports, energy storage materials, artificial tissue, and so on.

The development of a continuous, weavable multilayered CNT yarn with superior mechanical, structural, surface, and electrical properties opens the way for a wide range of structural and functional applications, including composites, intelligent fabrics, catalyst supports, and sensors. The layered yarn with a micrometer-sized hollow and a nanometer-sized porous electrically conductive wall is attractive for the development of novel biomaterials, including vascular, neural, and controlled drug- release materials. Finally, the successful fabrication of the textile yarn of CNT could stimulate the development of other types of layered fibers on an industrial scale.

Multilayered CNT yarns and products.

a) A CNT yarn obtained by continuous spinning for 5 h.

b) An arranged yarn spun on the spindle (scale bar 1 cm).

c) As-spun CNT yarn on the spool, showing that the yarn is continuous, uniform, and rewindable from the spool (scale bar 1 cm).

d) A mass of monodispersed as-spun fibers cut from a spool.

e) Morphologies of the as-spun CNT yarns. From top to bottom: optical microscopy images of the as-spun fiber viewed at the long edge, the short edge, a yarn lightly twisted, and a SEM image (scale bar 100mm).

f) A photograph of a plain, woven fabric consisting of 65_82 crossed lines of the as-spun yarn.

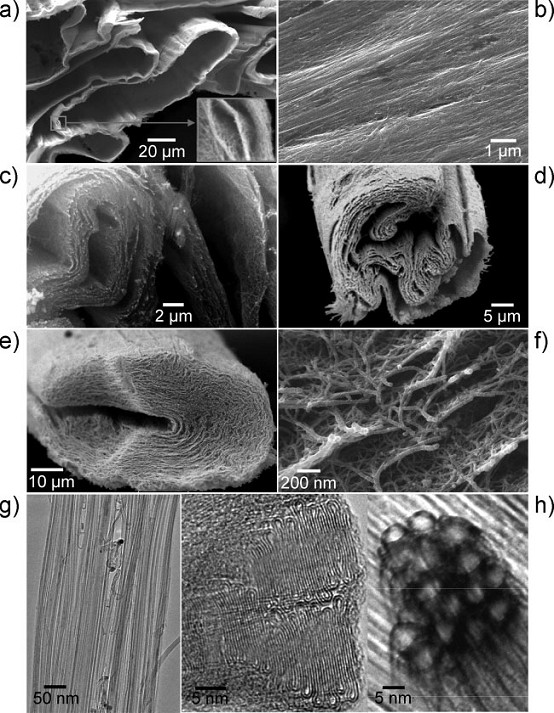

Microstructures of the multilayered CNT yarn observed by SEM (a–f) and TEM (g,h).

a) Cross-sections of a group of as-spun yarns, showing the hollow, multilayer microstructure (inset).

b) A yarn surface showing densely packed CNT bundles aligned along the fiber axis.

c,d) Cross-sections of a multilayer yarn after mechanical rolling. The yarns shown in (a–d) are spun with acetone densification.

e) A yarn showing more than forty layers packed along the fiber axis.

f) An enlarged region of the fiber in (e) showing an individual layer, which consists of a monolayer of crossed CNT bundles.

g) The CNT bundles observed by TEM.

h) An end of a CNT bundle showing DWNTs with a collapsed structure packed in a bundle (left) and with a round structure (right).

Properties of the multilayered CNT yarns.

a) A stress–strain curve of an as-spun yarn measured with a 10mm gauge length. The inset shows a photograph of the CNT yarn supporting five spanners, adding up to a total weight of 1.25 kg over a multifilament of the CNT yarn.

b) A cyclic tensile curve at 100 times cyclic loading between 1.0 and 6.5 cN.

c) Nitrogen absorption curve (from BET measurements) of the as-spun yarns.

d) Cyclic voltammogram of a CNT fabric supercapacitor (inset). |